Racing Toward 3-D Printed Electric Motors

Racing Toward 3-D Printed Electric Motors

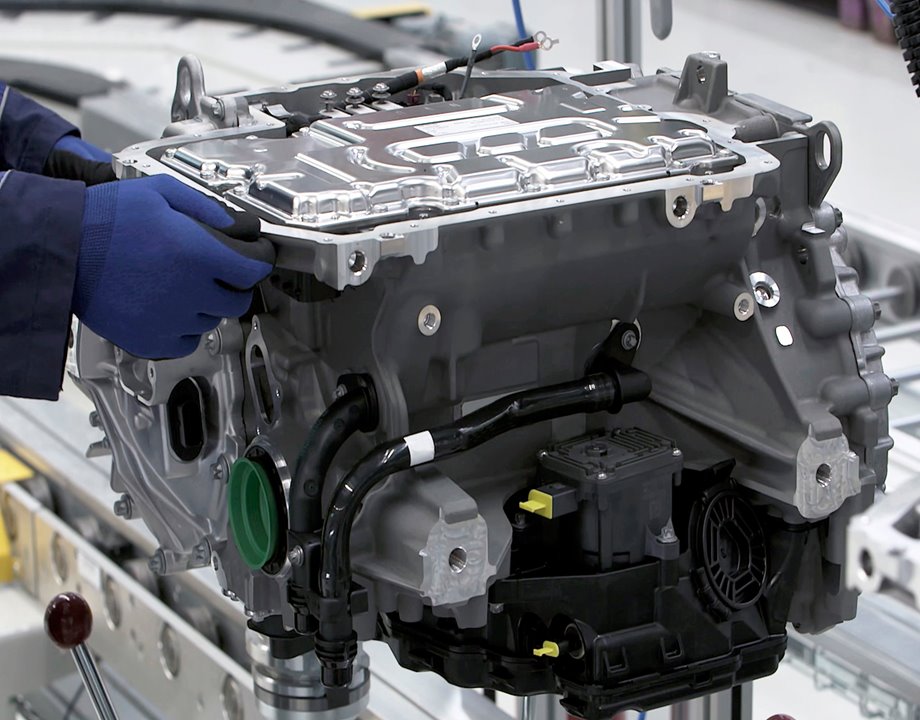

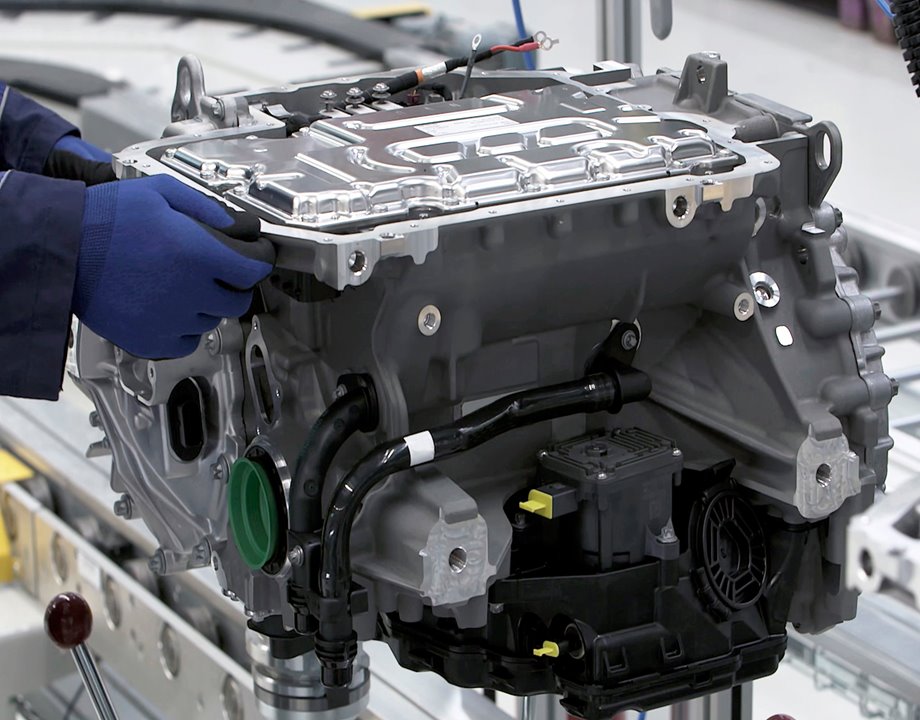

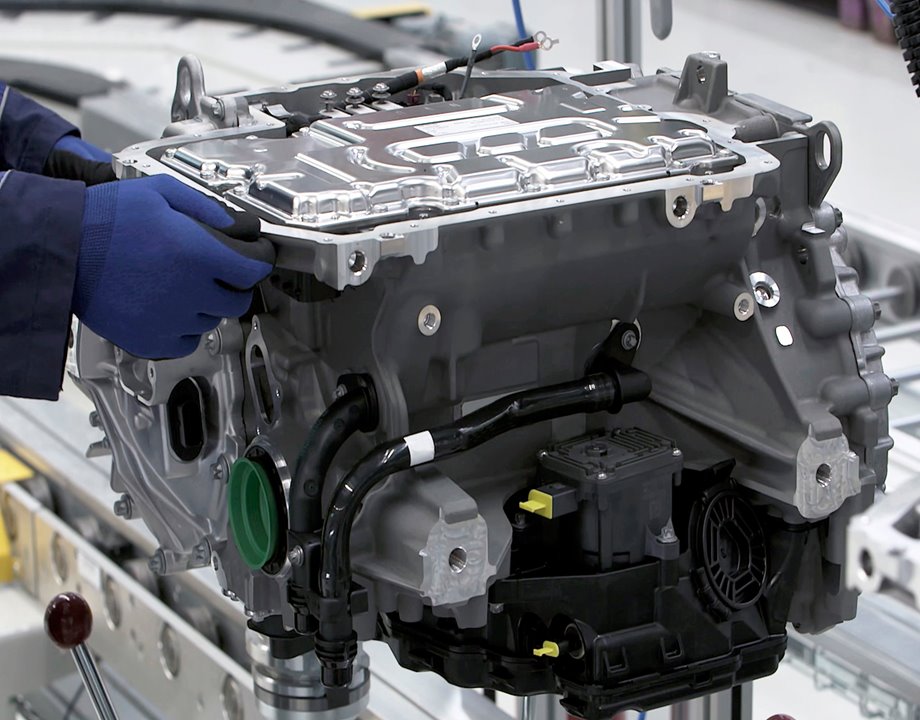

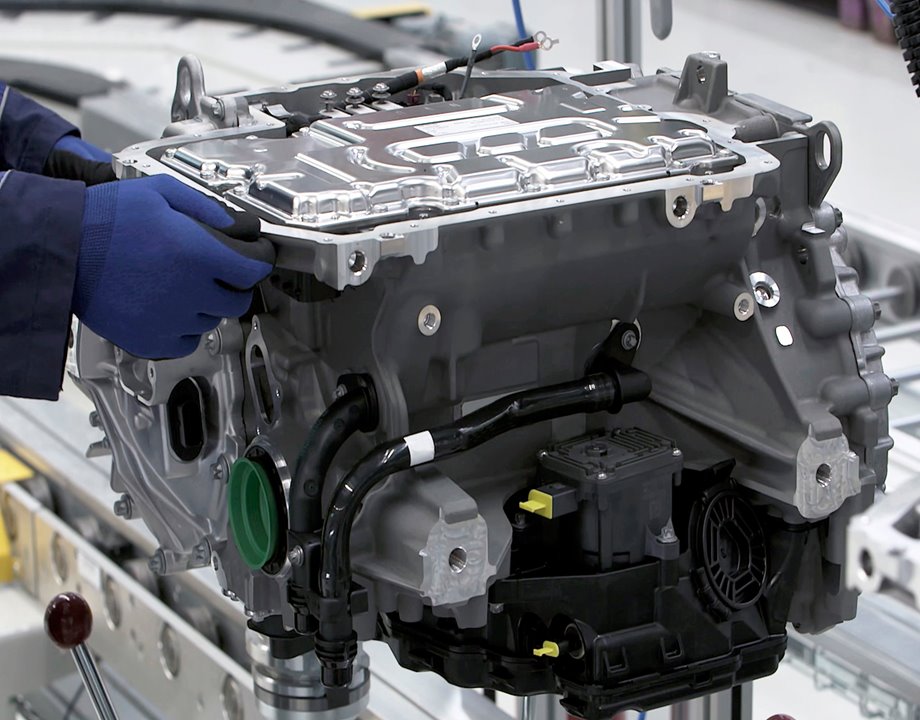

Engine parts and casing were 3D printed separately and joined together. Photo: Manufacturing Technology Centre

Electric motors haven’t seen much change in their material makeup—or design—since their inception. Now, researchers around the globe are studying the possibilities of a 3-D printed motor for weight reduction and performance gains.

Still, the 3-D printed electric motor remained only a theoretical construct until very recently. Recently, a team at the Manufacturing Technology Centre in Coventry, England, built an electric motor through additive manufacturing, with plans to build on that first attempt.

The researchers recently 3-D printed the major engine parts. They have already developed a way to print the motor casing, including the necessary cooling channels for their water-cooled engine.

Put the parts and the casing together and you have a completely printed electric engine. Though the printed parts are smaller and lighter than conventional motor components, the final result has higher output power. The printed motor is made up of fewer parts than its traditional counterpart, which can simplify manufacturing supply chains, cut running costs, and reduce assembly and inspection time, said Dan Walton, MTC technology manager for electrification. He led a cross-functional team of engineers who specialized in product design, additive manufacturing, materials, and simulation.

Walton is amused to think the group’s original plan was to further scientific thought about an electric motor produced via additive manufacturing.

“However, as the project progressed we realized that some of the 3-D printing technologies we were using were already suited for a motor,” Walton said. “So we decided to produce a few designs.”

Why all this work toward a printed electric motor anyway? Walton has a ready answer.

More for You: Using Micro 3D Printing for Short-Run Production

Additive manufacturing brings with it a design freedom that allows engineers to combine components in ways they couldn’t if the motor was to be manufactured traditionally. Benefits include:

Their repurposed engine showed a 10 percent savings in mass and a 30 percent reduction in size, mostly due to the capability to design and integrate components in new, space-saving ways, Walton said.

“The work was intended as a thought-provoking piece to show what was possible, so we didn’t test the machine to its limits,” he added. “However, a good rule of thumb is that moving from an air-cooled to a water-cooled electric motor can provide you with two to three times the power depending on the motor construction.”

He does cite a drawback to additive manufacturing.

“The AM process is undoubtedly slower than a high-volume manufacturing process,” he said. “It’s the reason why you are more likely to see an AM motor in an aerospace or motorsport application, rather than a mass produced electric vehicle.”

Reader’s Choice: 3D Printing Serves Up the Main Course

The process engineers use to design the AM motor casing and cooling chambers differs little from the design of traditional cast casings.

“As with many development projects, we start with requirements and limiting factors,” Walton said. “What does the motor casing to connect to? What stresses will it see? Where can I place the sensors and connectors? What material can I use?”

After answering those questions, the designers created a series of conceptual CAD models in which they mapped and visualized the available space.

“Often these concepts are much heavier than required, but it is an opportunity for us to consider the “design for assembly” challenges for the product,” Walton said. “It means we ask questions like: can I combine these parts? Do I need these fasteners? How do I put this motor together in the most efficient manner?”

They used a digital simulation and design tool called topology optimization that optimizes the shape of the parts for minimized mass. “The output of the tool is often a highly organic geometry that requires some user intervention to ensure the parts can be manufactured,” Walton said.

But the MTC team hasn’t stopped at swapping out parts inside a traditionally manufactured motor. They’ve actually designed and manufactured an entire electric motor from scratch, including the housing. Its big reveal is coming soon, Walton said.

“As part of the exercise, we made a like-for-like comparison between the traditional and the novel manufacturing technologies for a water-cooled motor," he said. "That means we can compare the effect of AM on cost, lead time, mass, volume, part count, and more.”

For the comparison, the team designed a traditionally manufactured motor housing, an AM housing and an “indirect AM housing,” in which a 3-D printed mold tool is used for casting. Those comparison numbers are also coming soon, but Walton did tease the results.

“We’re seeing some fantastic benefits with in regard to reduced mass, volume, and number of components,” he said.

Editor’s Pick: 3D Printing Steps into Housing

The team’s next steps? Further improvements.

“We’ve focused exclusively on the benefits of additive manufacturing as a replacement for the load-bearing components which aren’t active within the running motor,” Walton said. “But there’s plenty of opportunity for further improvement in this area,whether it’s new, stronger material alloys that allow for lighter-weight components or through further design to locate cooling channels closer to the source of heat generation.”

His team is also turning attention to the “active “ components within the motor.

“For example, the development of additive manufactured motor windings has the potential to achieve a real step-change in the performance of electric motors in the future,” Walton said.

Those goals are pretty far from the “theoretical” study of a 3-D printed electric motor the group originally undertook.

Jean Thilmany writes on technology and science from Saint Paul, Minn.

Still, the 3-D printed electric motor remained only a theoretical construct until very recently. Recently, a team at the Manufacturing Technology Centre in Coventry, England, built an electric motor through additive manufacturing, with plans to build on that first attempt.

The researchers recently 3-D printed the major engine parts. They have already developed a way to print the motor casing, including the necessary cooling channels for their water-cooled engine.

Put the parts and the casing together and you have a completely printed electric engine. Though the printed parts are smaller and lighter than conventional motor components, the final result has higher output power. The printed motor is made up of fewer parts than its traditional counterpart, which can simplify manufacturing supply chains, cut running costs, and reduce assembly and inspection time, said Dan Walton, MTC technology manager for electrification. He led a cross-functional team of engineers who specialized in product design, additive manufacturing, materials, and simulation.

Walton is amused to think the group’s original plan was to further scientific thought about an electric motor produced via additive manufacturing.

“However, as the project progressed we realized that some of the 3-D printing technologies we were using were already suited for a motor,” Walton said. “So we decided to produce a few designs.”

Why all this work toward a printed electric motor anyway? Walton has a ready answer.

More for You: Using Micro 3D Printing for Short-Run Production

Additive manufacturing brings with it a design freedom that allows engineers to combine components in ways they couldn’t if the motor was to be manufactured traditionally. Benefits include:

- Slashed low-production lead times, as tooling isn’t needed to 3-D print components

- Fewer assembly steps

- Fewer parts to design and manage

- Fewer pieces of manufacturing machinery needed for production, which would free up floor space and cut capital costs

Their repurposed engine showed a 10 percent savings in mass and a 30 percent reduction in size, mostly due to the capability to design and integrate components in new, space-saving ways, Walton said.

“The work was intended as a thought-provoking piece to show what was possible, so we didn’t test the machine to its limits,” he added. “However, a good rule of thumb is that moving from an air-cooled to a water-cooled electric motor can provide you with two to three times the power depending on the motor construction.”

He does cite a drawback to additive manufacturing.

“The AM process is undoubtedly slower than a high-volume manufacturing process,” he said. “It’s the reason why you are more likely to see an AM motor in an aerospace or motorsport application, rather than a mass produced electric vehicle.”

Reader’s Choice: 3D Printing Serves Up the Main Course

The process engineers use to design the AM motor casing and cooling chambers differs little from the design of traditional cast casings.

“As with many development projects, we start with requirements and limiting factors,” Walton said. “What does the motor casing to connect to? What stresses will it see? Where can I place the sensors and connectors? What material can I use?”

After answering those questions, the designers created a series of conceptual CAD models in which they mapped and visualized the available space.

“Often these concepts are much heavier than required, but it is an opportunity for us to consider the “design for assembly” challenges for the product,” Walton said. “It means we ask questions like: can I combine these parts? Do I need these fasteners? How do I put this motor together in the most efficient manner?”

They used a digital simulation and design tool called topology optimization that optimizes the shape of the parts for minimized mass. “The output of the tool is often a highly organic geometry that requires some user intervention to ensure the parts can be manufactured,” Walton said.

But the MTC team hasn’t stopped at swapping out parts inside a traditionally manufactured motor. They’ve actually designed and manufactured an entire electric motor from scratch, including the housing. Its big reveal is coming soon, Walton said.

“As part of the exercise, we made a like-for-like comparison between the traditional and the novel manufacturing technologies for a water-cooled motor," he said. "That means we can compare the effect of AM on cost, lead time, mass, volume, part count, and more.”

For the comparison, the team designed a traditionally manufactured motor housing, an AM housing and an “indirect AM housing,” in which a 3-D printed mold tool is used for casting. Those comparison numbers are also coming soon, but Walton did tease the results.

“We’re seeing some fantastic benefits with in regard to reduced mass, volume, and number of components,” he said.

Editor’s Pick: 3D Printing Steps into Housing

The team’s next steps? Further improvements.

“We’ve focused exclusively on the benefits of additive manufacturing as a replacement for the load-bearing components which aren’t active within the running motor,” Walton said. “But there’s plenty of opportunity for further improvement in this area,whether it’s new, stronger material alloys that allow for lighter-weight components or through further design to locate cooling channels closer to the source of heat generation.”

His team is also turning attention to the “active “ components within the motor.

“For example, the development of additive manufactured motor windings has the potential to achieve a real step-change in the performance of electric motors in the future,” Walton said.

Those goals are pretty far from the “theoretical” study of a 3-D printed electric motor the group originally undertook.

Jean Thilmany writes on technology and science from Saint Paul, Minn.

.jpg?width=850&height=566&ext=.jpg)